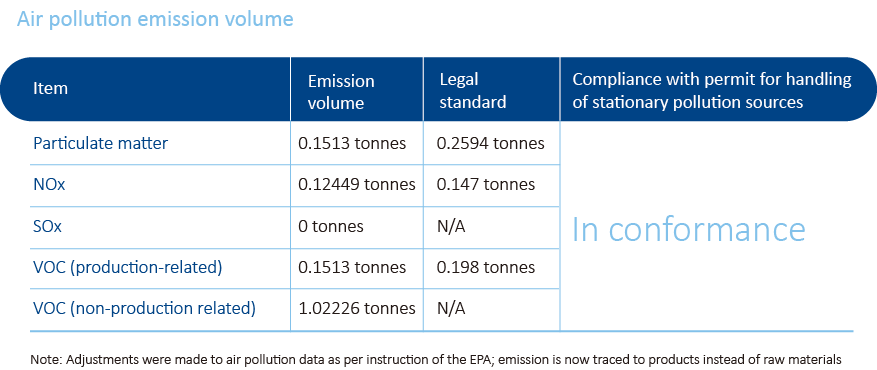

Air Pollution Prevention and Control

Degree of conformity with emission standards of stationary pollution source operating permit Compliant

From an environmental management perspective, we have stopped the use of toxic chemicals since 2011, and acquired permits based on air, water, and waste-related laws and regulations; and also controlled the pollution discharge to conform with the environmental protection standards.

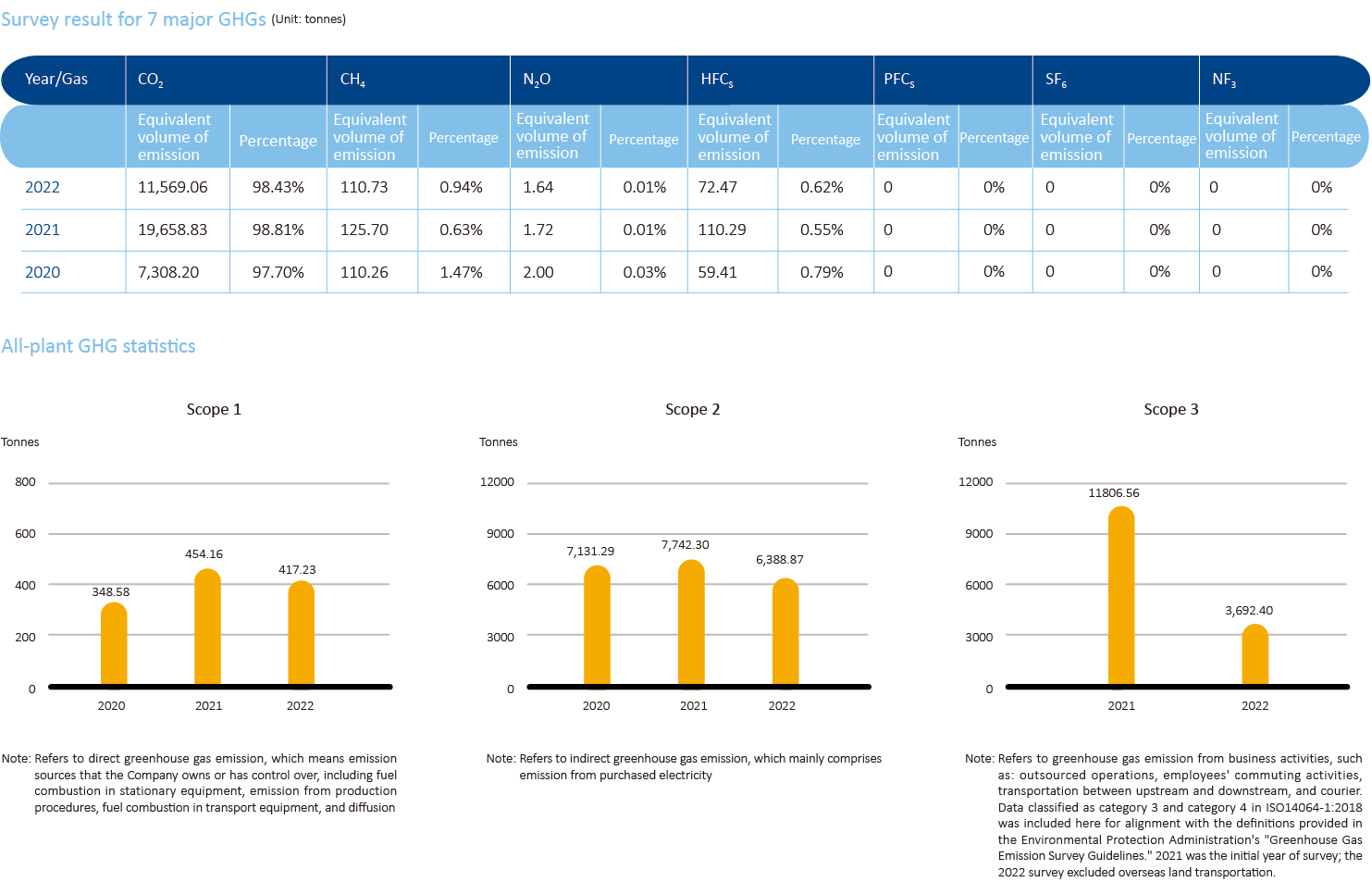

In order to slow down the impact of climate change under global warming, we worked to strive for a perfect balance between business development and environmental protection. At the same time, we passed the ISO14001 environment management system certification and proposed the following commitments.

Degree of conformity with emission standards of stationary pollution source operating permit Compliant

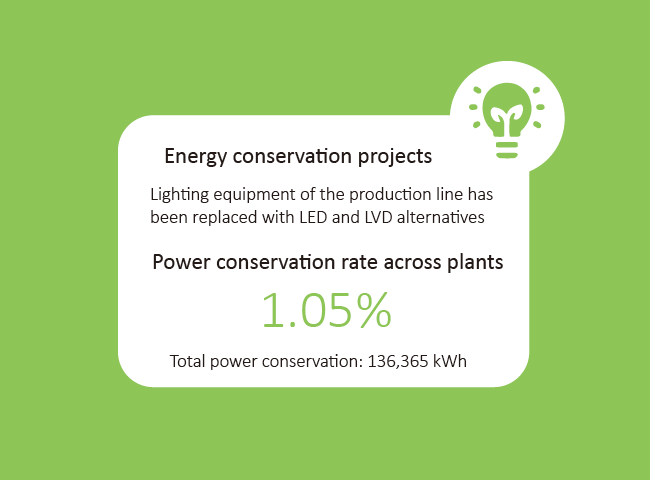

Power saving rate of the year: 1.05%

Increase water reuse: 5%

Commission an independent verification by SGS

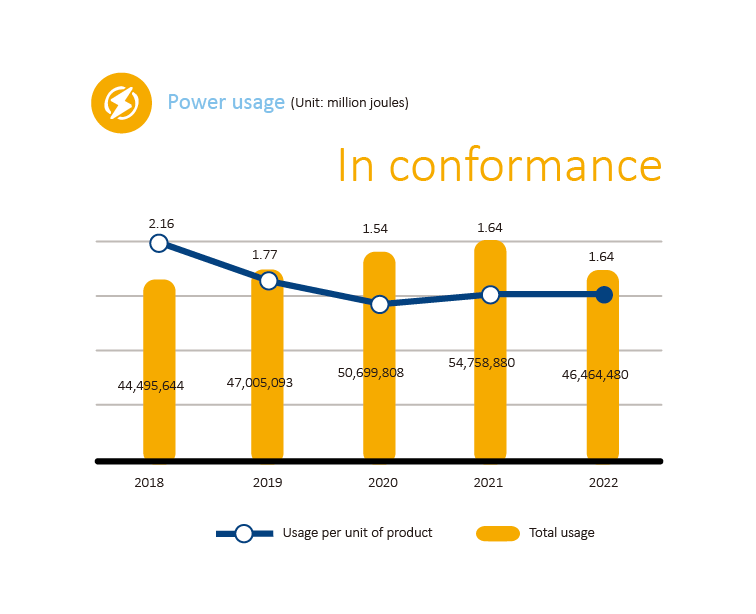

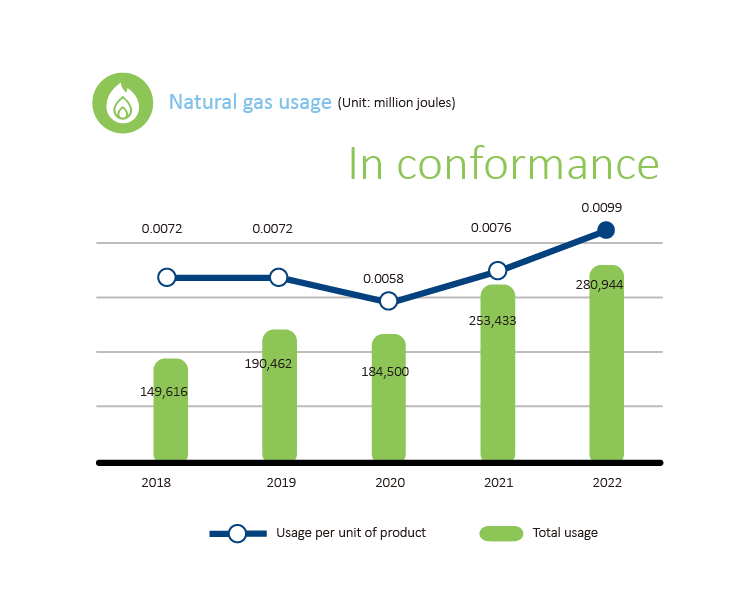

Taiwan Fu Hsing monitors energy usage on a yearly basis and makes persistent efforts to optimize energy efficiency. The types of energy used included electricity, natural gas, and diesel. 46,464,480 million joules of electricity was used in 2022, representing a 18% reduction from the previous year. The factories still managed to execute energy conservation projects and replace inefficient equipment so effectively that they reported a 1.05% power conservation rate for the year according to the Energy Administration Act, which was better than the 1% requirement imposed by the government. The Company used 280,944 million joules of natural gas, which was within the level approved by the environmental protection authority (91,800m3/year; equivalent to 3,304,800 million joules/year). The Company used 499,265 million joules of diesel, increasing significantly from the previous year due to the acquisition and more frequent use of diesel vehicle. Overall, the Company consumed 47,577.689 GJ of energy in 2022.

Taiwan Fu Hsing duly implements strategies to reduce resource consumption and continues to enforce energy and carbon reduction measures. The projects executed in 2022 mainly revolved around equipment improvement, and the outcomes were as follows.

With regards to the purchase of green power, the "Regulations for the Management of Setting up Renewable Energy Power Generation Equipment of Power Users above a Certain Contract Capacity" requires all electricity users with more than 5,000 kW of contracted capacity to install renewable energy equipment, and given Taiwan Fu Hsing's contracted capacity of 3,205 kW, there has been no need to set up renewable energy equipment.

Taiwan Fu Hsing applies stringent control over particulate matters, nitrogen oxides (NOx), sulfur oxides (SOx), and volatile organic compounds (VOC). All emission data was calculated in accordance with the Environmental Protection Administration's "SOx and NOx Emission Coefficient and Efficiency for Reporting of Air Pollution Control Charges by Public and Private Stationary Pollution Sources" after taking into consideration the production procedures and pollution sources associated with the industry. A third-party testing company has been engaged to conduct regular tests on whether the emissions conform with standards. Air pollutants discharged in 2022 were entirely below the government's emission standards.

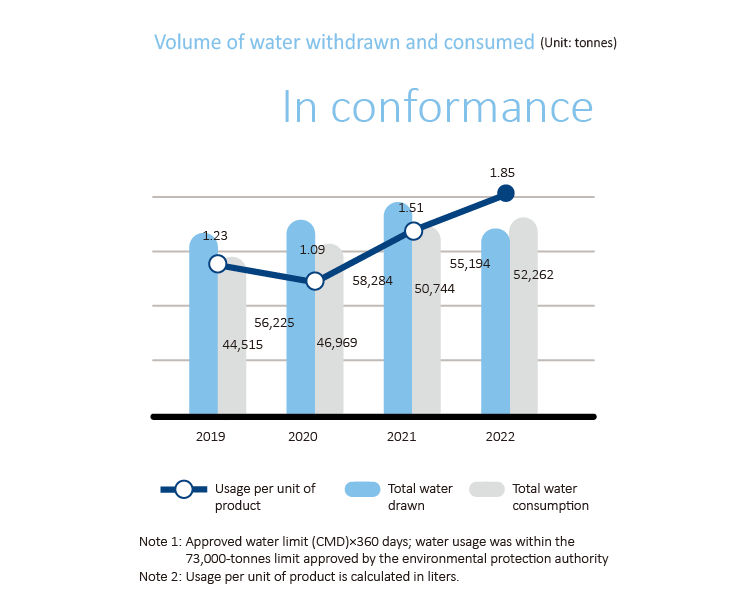

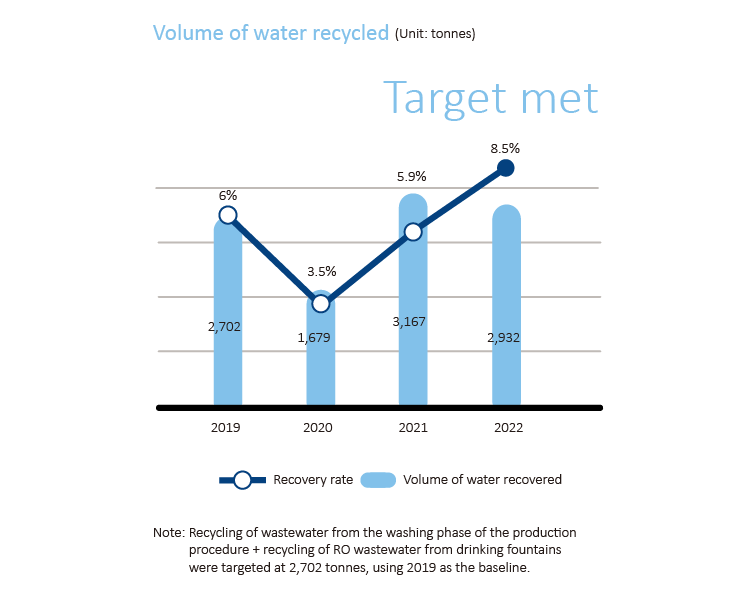

Since we used 100% tap water instead of groundwater, there were no problems of over-pumping of groundwater and land subsidence. Water drawn in 2022 totaled 52,262 tonnes, which was within the range approved by the environmental protection authority. We have also implemented water conservation projects to recycle water from the washing phase of the production procedure, and to recycle and reuse RO wastewater from drinking fountains. The factories recycled 2,932 tonnes of water in total in 2022, which exceeded our initial target.

Water shortage is biggest crisis that businesses must prepare for particularly at a time of extreme weather conditions, which is why the Company will continue devoting attention to the development and improvement of water conservation measures and recycling of production water in the future.

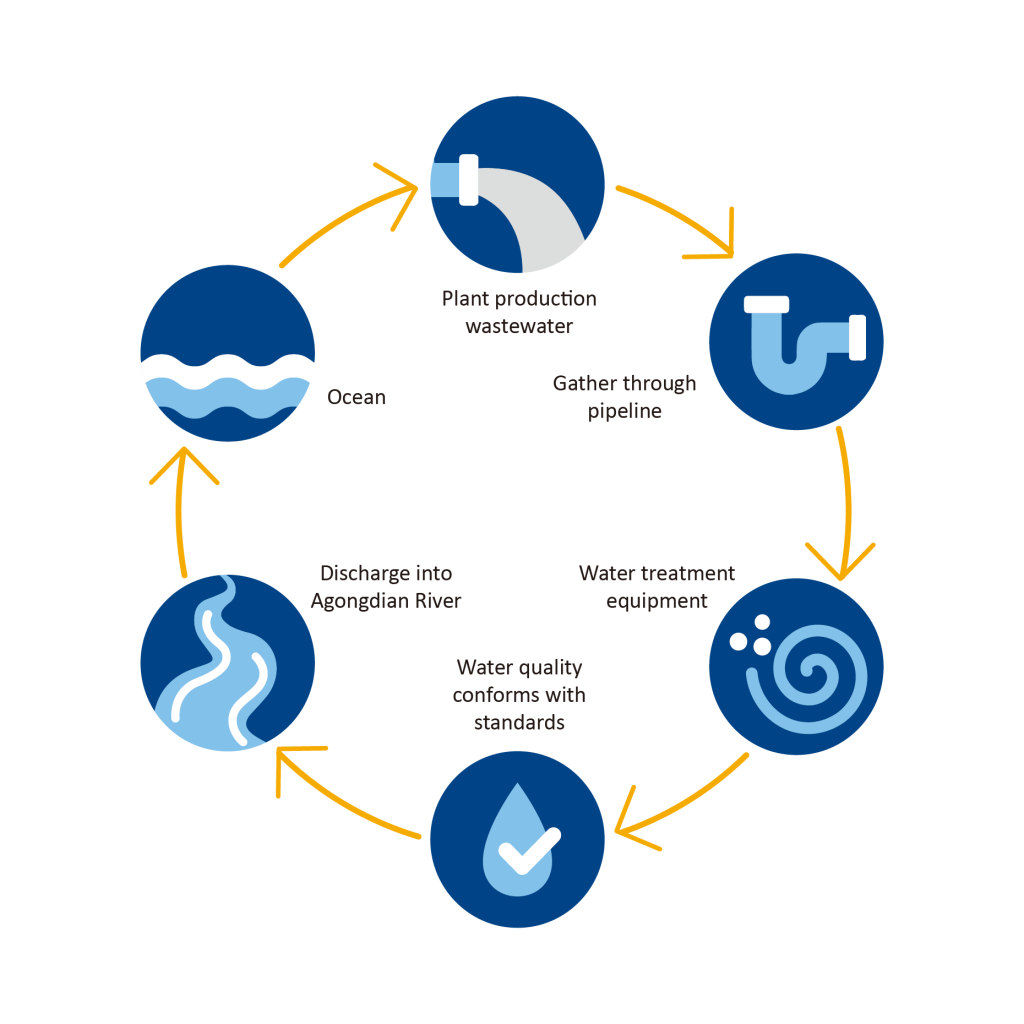

The process wastewater generated from the factories is delivered through the pipeline to the wastewater treatment equipment. Once the quality meets the wastewater discharge standard set forth in the government statutory and regulatory provisions, the treated wastewater is discharged to the Agongdian River Basin which eventually leads to the ocean. Once every half year, we entrust a certified inspection institution to test our wastewater quality and the test results have met the water quality standard set forth in current laws and regulations.

| Item |

Result

first half of the year / second half of the year

|

Standard in Current Laws and Regulations | Compliance | |

|---|---|---|---|---|

| water temperature(°C) | 31.3 | 31.2 | 38 | qualified |

| PH | 7.8 | 7.0 | 6.0~9.0 | |

| SS (mg/L) | ND | 5.7 | 30 | |

| COD (mg/L) | 40.7 | 39.3 | 100 | |

| Oil (mg/L) | ND | ND | 10 | |

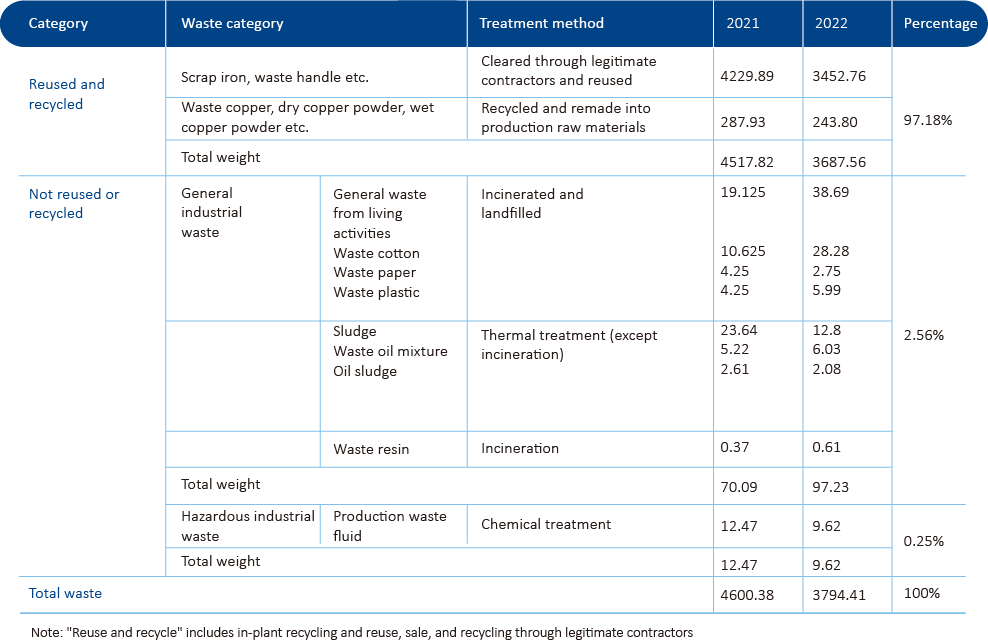

"Reduction and recycling" are the two main waste management approaches of Taiwan Fu Hsing. By reducing waste at the source and recycling/reusing the waste produced, the Company is able to minimize harm to the environment while at the same time reduce waste treatment costs. The factories reused 97.18% of the waste produced in 2022; the remaining 2.81% was cleared through legitimate contractors depending on waste characteristics.

While placing the same value on environmental protection and industrial development, we not only take our corporate social responsibility seriously, but also engage our employees in environmental protection activities.